Patented Innovations - International Solutions

CIP Tank Cleaning Hose Reel Systems

- Safer CIP hose handling

- Reduced confined space entry

- Electric motor for staged cleaning

- Safer rewind speeds

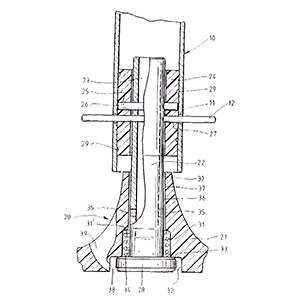

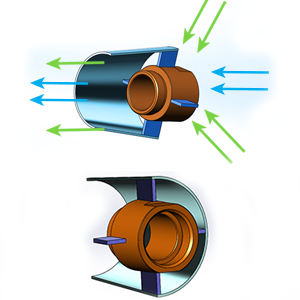

M-Series Tank Cleaning Nozzle

- Patented Flow-Step technology

- Low atomising - more impact

- Self cleaning design

- Direct spray ball replacement

Vehicle and Static Fire Protection BM Nozzles

- No o-ring protective cap design

- Patented nozzle orifice foil cover system

- Various flow rates and spray angles

- Unique pintle / foil perforation system

Snap Disc Shower Nozzles

- Eliminates disc misalignment

- No threads no tools

- Easy pre-assembly

- Positive seal / location

- Can only be installed one way

SD Stainless Shower Disc Nozzles

- Precision stainless shower nozzle

- Universal Fit

- Use in Snap-Disc easy fit shower head system

- Various flow sizes and profiles available

Ruby Needle Jet Shower Nozzles

- Unique no adhesive construction

- Resist premature orifice dislodgement

- Conventional washer and o-ring seal options

- Bullet design & extension tube disc option

Ruby Trim Needle Jet Nozzles

- Patented orifice insert system

- Mechanically assembled, no adhesive construction

- Longer life and pressure range

- Optional filter screens for all pipe sizes

Mini M-70LF Washdown Gun

- Unique low flow pintle

- Approved smart-water star rating

- Lower flow than standard Mini M-70

- Water saving with variable spray pattern trigger action

Spray Chilling Nozzles for the Meat Industry

- Unique design from years of experience

- Special diaphragm check valve for even opening and closing pressure

- Low drift nozzle technology for targeted cooling & wetting

- Various twin and single spray nozzle options available

Custom Spray Lances, Pipework & Spray Bars

- Complete spray lance and spray bar systems

- Full NDT and QA standards to ASME

- Unique connection systems threaded, flanged and weld

- Stuffing boxes for oil, gas and petrochemical and applications

Fire Protection Hose Reels – Fire Dog

- Only fire reel with Easy Deploy® auto declutching reduces strain injury

- Flat-Winder® auto hose layering. Single person operation with remote control

- Safe-R-Reel® gearbox designed for safer rewind speeds protecting personnel and property

Mining Hose Reels – Pit Bull™

- Galvanised low maintenance heavy duty construction

- Direct drive gearbox. The safest speed control available for manual and power rewind

- Auto declutching for easier payout without injury

- Optional push button rewind for one person or truck mount applications

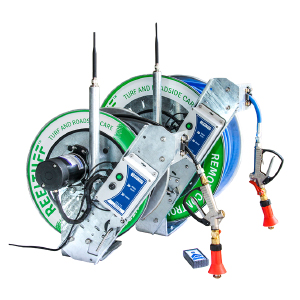

Turf Care Hose Reels – Reel Tuff™

- Reel in Control. Long range remote control with channel hop

- Patented no-belt direct drive system

- Long life galvanised finish does not require painting

- Quick change stainless hubs on all models

Testimonials

I find what sets the M-Series apart from other CIP spray devices is the self cleaning aspect. Its reassuring knowing that I don't have to hold concerns about residual soiling from previous cleaning cycles building up and remaining within the nozzle head.

For the last 10 years I’ve been buying products from Spray Nozzle Engineering. The Mini – M70 LF water gun has been the only gun that works for us due to the low flow and pressure. We use a lot of water in the food industry so it has saved us lots of money in the long run. It’s a very high-end product that is indestructible and it last long when compared with other guns in the market. I have used many other brands in the past and I couldn’t find the quality that the Mini-M70 LF has. Spray Nozzle engineering apart of selling this unique product, they have great customer service, problem solving skills and the best of all, they have a solution for any problem in the industry.

Our factory has used Click&Dry milk-spray nozzles and Drip-Pro Check Valves for approximately 10 years. During this time there has been considerable development in this area of our operation, and this has been made possible by an innovative, can do approach by both parties. We . also made the change to a water start/stop on the drier during this time. However, we noticed that on a stop, there were water drips from the nozzle and this would foul the tower con and fluid bed below. This eventually would lead to scorched particles in the powder and associated product downgrades. To overcome this problem, Spray Nozzle Engineering developed a non drip nozzle (Drip-Pro Check Valve version of the Click&Dry Nozzle) which we trialled and continue to use with success to this day. Spray Nozzle Engineering have been an effective supplier to our business over the years. Service and supply has never been an issue, and they are able to train operators to use and look after the product. There is a continuous improvement approach with products made more reliable, and easier to use. From an overall cost point of view we have found the Spray Nozzle Engineering products to be competitively priced. Our current nozzle bodies are over 3 years old and these are used 24/7 continuously. We are only now planning for their replacement. I have no hesitation to recommend Spray Nozzle Engineering.

In my opinion Click&Dry series which we use at the moment has number of advantages as: Durability of nozzles & accompanied parts, simplified assembly of nozzle which saves set up time, guaranteed application and lower risks in regards to failure during run or complexity of parts operation, more efficient cleaning of cap and internal sections.

We currently have “Head Cleaning” units supplied by Spray Nozzle Engineering Pty Ltd, fitted to six of our Silos and found them to be up to the task. In the past 18 months we have only had to replace 3, which I find acceptable given the amount of CIP’s performed and the chemicals used.

TOP FIVE REASONS TO BUY NOZZLES FROM US

We stand ahead from our competitors as a global specialist manufacturer of unique patented spray nozzles and related products which are exported to the world.

We provide design and application engineering to provide truly solutions to any industry.

-

1Experience in Spraying Technology

Since 1988 Spray Nozzle Engineering has been leading the way towards innovation and product delivery. Not content to simply supply a product, Spray Nozzle Engineering has a wealth of experience expanding generations.

With a team of specialist skills from around the globe, all working to go beyond the supply process, Spray Nozzle Engineering is truly your total spraying solutions.

-

2Leader in Innovation and Nozzle Development

By working closely with all stake holders end-users, designers and constructors alike, our advice continues to introduce new technology and custom designs, with the support of fully equipped spray nozzle test laboratories for pattern analysis and spray droplet size testing.

In conjunction with our own in-house design and engineering teams, along with our key supply partners are amongst the world leaders in there field, Spray Nozzle Engineering can offer a total spraying solution design and delivered both locally and globally.

-

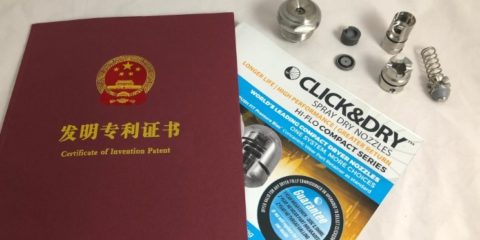

3Patented Technology Exported Globally

Working across all process disciplines Since 1988, allows Spray Nozzle Engineering to draw upon a wealth of application and design experience. As a customer focused solutions Engineering Group, Spray Nozzle Engineering now exports globally, with world leading process solutions in fields as diverse as spray drying, tank cleaning, fire protection, check valves and more. Partnering with our customers to solve process problems, increase quality and reduce costs, our technology has been recognised by some of the worlds largest companies in their fields, along with technology innovation awards.

Our Innovation program has seen the successful deployment of several new patented products, that are now setting the standard world wide in there fields. Included are the new range of PEFS or Pre Engineered Fire System Nozzles, with unique orifice protection foil covers and orifice pintle insert technology that guarantees foil cover deployment, now one of the mining and off road sectors leading on board fire nozzle for all foam and water spray systems for fire protection.

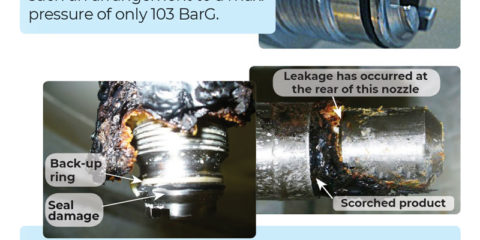

Another major success for the food, pharmaceutical and dairy process industries, has been the latest design generation of the Spray Nozzle Engineering Click&Dry Spray dry atomising nozzles. Spray dry nozzles (Click&Dry) and check valve systems (Drip-Pro), used in high pressure spray drying plants for powder production, have introduced many patented world first innovations in this field. Click&Dry’s major improvements include safety sealing and thread designs that ensure code compliance and explosion risk reduction in plants world wide. Recent patents include our latest hygienic internal nozzle cap designs for infant formula production. These caps have smooth chamber allowing easy access for cleaning, making them the most hygienic caps in the market. Our hygienic cap and concentric wear part designs are also leading in major cost reduction technology for powder production equipment. We introduced the optional check valve called Drip-Pro, which holds many patents and unique design features in itself. The Drip-Pro check valve is now used by many of the world’s largest dairy companies.

-

4Great Customer Service

Originally covering Australasia from our own sales offices across both Australia and New Zealand, Spray Nozzle Engineering now covers the Globe with both out of hours support and a network of world wide dealers. Whether you wish to converse in English, Spanish, Portuguese, Mandarin, Filipino, Hebrew, Indonesian, or even Te Reo Māori, we’ve probably got you covered, but if we haven’t, please let our actions and service speak loader than words! Just email or call, and lets begin a conversation.

Whether you are in need of urgent assistance or simply have a product or application enquiry, you can rely on Spray Nozzle Engineering for your total spraying solutions.

We continue to provide the same prompt service that has made us a market leader since 1988. Providing ongoing support to help our customers select the right spraying solution to suit their requirement.

Whether you need a fluid mechanics solution for spraying, coating, cleaning, blowing, drying, atomising, lubricating or more, or perhaps, spray guns or related products, your satisfaction is our ultimate goal. Perhaps you can’t find what your looking for on our website, or are unsure, well, we are here to help with assistance the good old fashioned way, by talking to a real person. Visit our Testimonial page and see what our clients are saying about us.

-

5Exporting to the World

From our origins providing sales-service and support throughout Australasia, with offices across Australia and New Zealand, Spray Nozzle Engineering now exports to every major market and process industry across the globe. With specialist partner distributors in your region and more joining every year, the Spray Nozzle Engineering can work with you through a dedicated partner or directly as an OEM (Original Equipment Manufacturer) or manufacturer.

Spray Nozzle Engineering maintains a large stock offering with well over 20,000 different spray nozzles and associated products for quick product turn around, and delivery times and stocking strategies and price points to meet your needs, when you need it. Just ask us today how we can bets partner with you to achieve the outcomes you are looking for. Become a Distributor