Spray Chilling Nozzles for the Meat Industry

- Unique design from years of experience

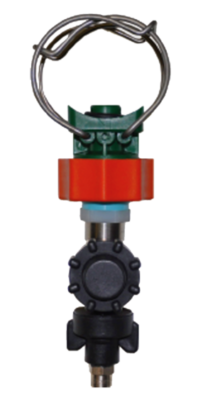

- Special diaphragm check valve for even opening and closing pressure

- Low drift nozzle technology for targeted cooling & wetting

- Various twin and single spray nozzle options available

Spray chilling nozzles for the meat processing industry

Spray Nozzle Engineering provides spray chilling nozzle assemblies to suit your choice of nozzle requirement:

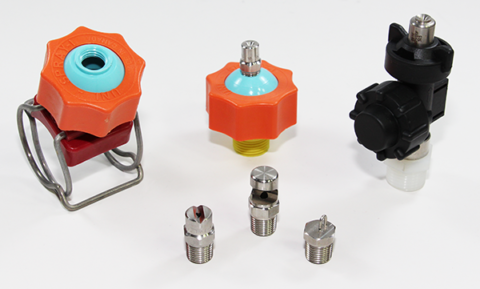

- Full cone nozzles

- Hollow cone nozzles

- Flat fan nozzles

Spray nozzle patterns are dependent on your application, whether static or mobile.

Unique to Spray Nozzle Engineering, Spray Chilling system is the Wilger Comb-Jet nozzle body and diaphragm check valve system. The complete assembly allows both installers and maintenance fitters to always have nozzles in the correct orientation. The improved Wilger check valve delivers consistent shut off and opening pressure without the problem of dripping.

Contact Spray Nozzle Engineering today for free advice on total spraying solutions for your food processing needs.

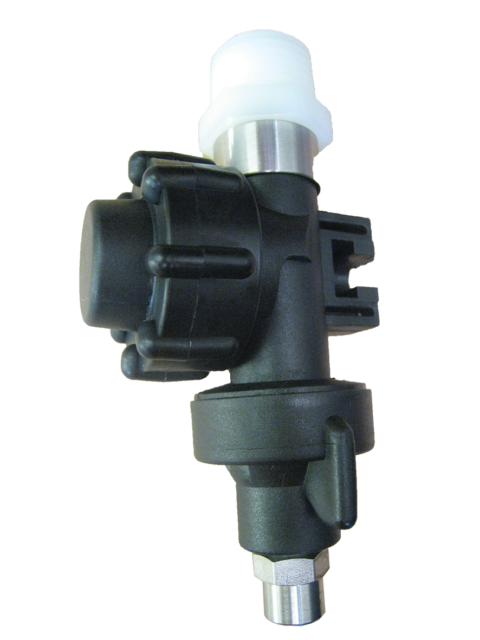

- Clamps are available in custom sizes. Clamped mounting has a rigid pipe system higher pressure rated compared to other systems.

- Reinforced stainless screwed fittings avoids cross threading and thread damage for longer life and serviceability

- New larger filter area on specific models means longer maintenance intervals

- New Wilger Optional Drift reduction nozzles, larger droplets means less drift, better cooling efficiency, easy removal design for maintenance

- Stainless steel bolted or clamped nozzles available in full cone, hollow cone, flat fan and flood design Various flow rates available for different carcass sizes