M-Series Tank Cleaning Nozzle

- Patented Flow-Step technology

- Low atomising - more impact

- Self cleaning design

- Direct spray ball replacement

M-Series: Efficient tank cleaning nozzle saving water and chemical usage

CIP spray nozzles designed to provide superior tank cleaning results at low operating pressures. Your solution to cleaner tanks with less water. Use M-SERIES tank washers with patented Flow Step Technology as a direct replacement for spray balls, delivering more efficient spray distribution, greater impact and faster C.I.P cycles. This means less waste water and low-chemical treatment costs, saving you time and money.

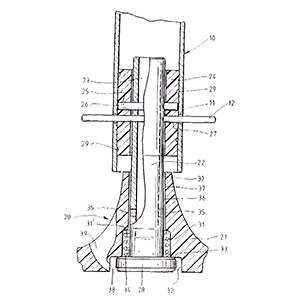

A step ahead with patented FLOW STEP technology

A unique patented stepped rotor design is powered by the cleaning fluid itself. The rotor steps are strategically arranged to channel the cleaning fluid into distinct concentrated streams of water to hit tank surfaces where they are needed most. These streams impart a greater hydraulic impact whilst reducing non-productive spray mist. Reduction of spray mist allows the formation of larger spray droplets from these step formed jet streams, which provides a higher degree of washing impact and more efficient wetting in comparison to competitive units

A unique patented stepped rotor design is powered by the cleaning fluid itself. The rotor steps are strategically arranged to channel the cleaning fluid into distinct concentrated streams of water to hit tank surfaces where they are needed most. These streams impart a greater hydraulic impact whilst reducing non-productive spray mist. Reduction of spray mist allows the formation of larger spray droplets from these step formed jet streams, which provides a higher degree of washing impact and more efficient wetting in comparison to competitive units

Your biggest step forward is to replace spray balls with the M-Series tank washer

The M-Series tank cleaning nozzle makes similar styles of tank washers and spray balls virtually obsolete. This is achieved by a number of unique patented features including Flow Step technology helping ensure superior hydraulic impact, a more thorough tank clean and less trouble in operation. The benefits gained allow increased cleaning efficiency and shorter cleaning cycles, providing major savings in water and cleaning chemical usage. This equals major cost savings to the operator.

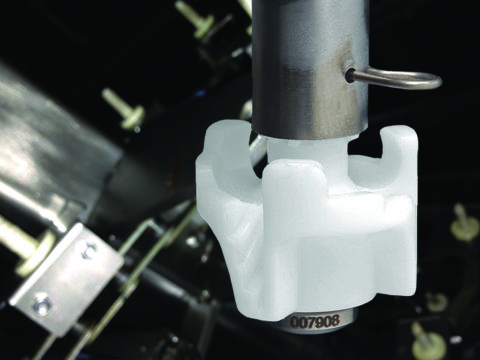

Patented self-cleaning action was the next step to improve reliability

Unique patented self-cleaning features of the M-Series tank cleaning nozzle offers major improvements for trouble free operation which sets us apart from the competition. This is achieved via a special bearing system that allows typical fluctuations in water pressure to purge any obstructions away from the bearing surfaces. Competitive washers can readily allow obstructions to jam within the bearing surfaces and impede rotation.

No lubrication is required other than the cleaning fluid itself and there are no ball bearings to lock-up, corrode or break down.

No lubrication is required other than the cleaning fluid itself and there are no ball bearings to lock-up, corrode or break down.

A material for every application

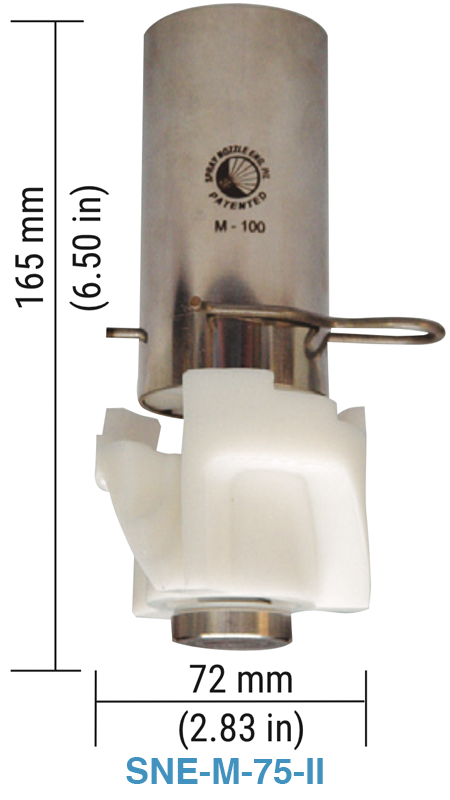

The M-Series tank cleaning nozzle consists of a standard shaft/body manufactured in a high grade stainless steel (AISI 316), with a rotor and flow director available in a choice of (FDA approved) materials: ACETAL-CoPolymer††, PVDF or PTFE. Full PTFE units are also available.

Full material certification and traceability are available on request.

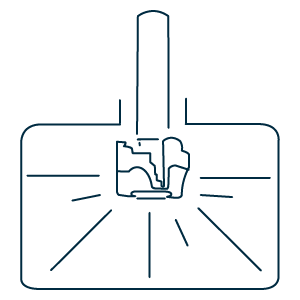

A true 360° Spray

Special emphasis is placed upon backward cleaning at points of entry, along with a concentrated forward wash-jet to assist cleaning items such as centralised agitators etc. The M-Series produces a superior cleaning action in a true 360 degree spray† when compared with similar cleaning devices.

Customise your M-Series washer

To control flow, the M-Series tank cleaning nozzle uses a standard 10-slot flow director which is specially designed to provide superior tank cleaning results at reduced pressures and flows. If your needs are special, custom units using non-standard flow directors and rotors can help tailor your flow and performance to suit specific requirements. Slot combinations of 4, 6, and 8 are also available upon request.

M-Series for every application

The M-Series tank cleaning nozzle sanitary design is ideal for CIP (Clean-in-place) tank cleaning applications in the wine, food and beverage, dairy, chemical, pharmaceutical and a wide variety of other applications and industries. Contact us with your special requirements.

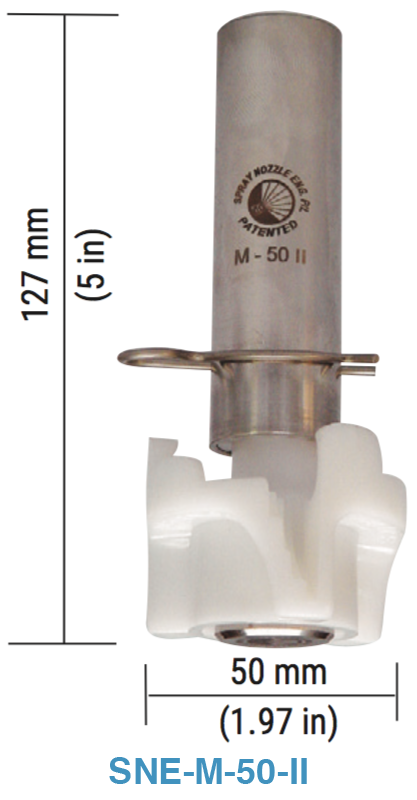

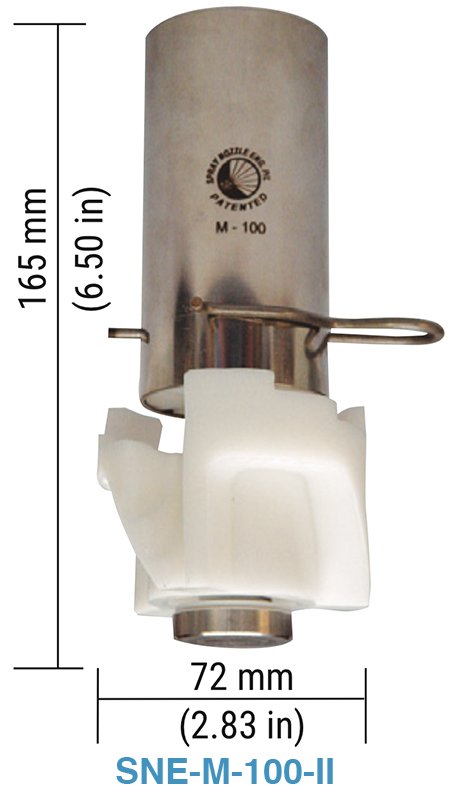

Connection: Standard male threaded 1/2″ BSP pipe. (NPT and other connections available) |

Connection: Standard butt weld 1 1/2″ O.D. Tube. (Special order connections available) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Connection: Standard butt weld 1″ O.D. Tube. (Special order connections available) |

Connection: Standard butt weld 2″ O.D. Tube. (Special order connections available) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Operation: Self operated by cleaning fluid Pressure: Recommended 1.5 BarG min (22psi) Temperature: Acetal 120°C (248°F) Max – PVDF 120°C (248°F) Max – PTFE 150°C (302°F) Max |

The M-series range of rotating tank cleaning nozzles are used in industry applications such as:

-

Dairy and Food Processing

- Milk silos

- Process vessels

- Duct cleaning

- Filling machines

-

Wineries and Breweries

- Process vessels

- Wine tanks

- Fermentation vessels

- Keg cleaning

-

Pulp and paper

- Process vessels

- Broke chests

- Stock chests

- Head box

-

Chemical processing

- Process vessels

- IBC tanks