Reduce Confined Space Entry with Vessel CIP Solutions – Pharmaceutical

Spray Nozzle Engineering offers solutions for the pharmaceutical and para-pharmaceutical industries. Whether dry or wet, tablets or injectables, personal care or veterinarian and animal health products, Spray Nozzle has a product or system to assist in better process outcomes.

With products for use on all parts of the system, from raw material batching and blending, distribution and coating, spray drying, to batch CIP cleaning systems, to packaging aids such as Air knives, blowing and more, Spray Nozzle Engineering can help.

Spray Nozzle Engineering can assist you choosing the right nozzle for coating, cleaning, lubrication, or blowing application.

Spray drying is a specialist area that is covered by our unique engineered and patented products. The Click & Dry series of Spray Dry Nozzles is a common method used to dry many temperature-sensitive materials like foods, chemicals and pharmaceuticals. Spray Nozzle Engineering offers Click&Dry spray nozzles in many configurations to suit your application and were the first to design a nozzle specifically for improved spray dry nozzle hygiene; called Hygiene Plus.

The company also manufactures the M-series Tank Cleaning nozzles. Ideal for tank and VAT cleaning in the pharmaceutical industry, the M-Series can be specified with full material traceability and part ID Number identification, to use as part of your validation process.

Our nozzles and product range are suitable for:

- Spray Drying

- Washdown an foam applications

- Spraying and Coating

- Cleaning

- Sanitising

- Tank cleaning (CIP)

- Drying and blowing

Automatic Spraying Solutions – Pharmaceutical

Mini M-70LF Washdown Gun

- Unique low flow pintle

- Approved smart-water star rating

- Lower flow than standard Mini M-70

- Water saving with variable spray pattern trigger action

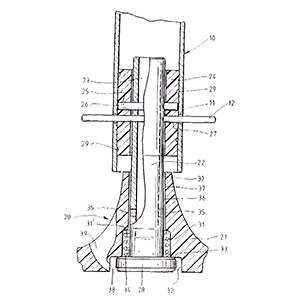

M-Series Tank Cleaning Nozzle

- Patented Flow-Step technology

- Low atomising - more impact

- Self cleaning design

- Direct spray ball replacement

CIP Tank Cleaning Hose Reel Systems

- Safer CIP hose handling

- Reduced confined space entry

- Electric motor for staged cleaning

- Safer rewind speeds