Click&Dry Spray Dry Nozzles

- Improved hygienic internals

- Axial Seal stops radial O-ring pinch leaks

- Low bearding outer cap design

- Reduced operating costs

Click&Dry™ Spray Dry Nozzles: Longer Life | High Performance | Greater Return

Visit our dedicated website to see our Click&Dry product range: www.spraydrynozzle.com

Benefits

- Improved nozzle hygiene

- No weld spray dry nozzle conversion caps – THE NO COST upgrade solution

- Long life wear parts

- Reduced bearding giving longer run times

- Long life swirl and CCT (Concentric Clasp Technology)

- Improved sealing to prevent leakage o-ring pinch damage

- Lower operating cost – reduced wear part breakages

- Designed for code compliance

- Low thread galling – anti-seize technology

Choosing CLICK&DRY™ spray dry nozzle not only delivers a product that reduces operating costs, extends wear life and improves powder quality, but you now also receive the best product support for your spraying needs.

It’s all about hygiene, quality, performance, productivity and reduced operating costs.

Product range:

Latest Spray Dry Innovations

Click&Dry™ spray dry nozzle has the latest innovations in 40 years of high pressure spray drying with nozzles. We are committed to delivering new breakthrough innovations to solve spray dry nozzle problems such as hygiene, quality and high on-going costs.

Highest Standards

Our nozzles are made with the highest quality materials and innovations to ensure the best results. We are so confident in the longevity of our proven Click&Dry™ system, that in the highly unlikely event that you experience a problem, we offer you the exclusive replacement warranty.**

Reduce Hard Wear Costs

With our latest innovations designed to improve hygiene and save hard wear costs. In fact, you could halve your hard wear use* while improving hygiene. Explore the spray dry nozzle range that gives you up to 4 years hard wear replacement warranty**.

* Data from 5 year comparative analysis of select plants. Usage reduction may vary depending on some processes and product.

**Available on select models. Refer to our Warranty page for more information.

Application Gallery

Visit our spray dry nozzles gallery

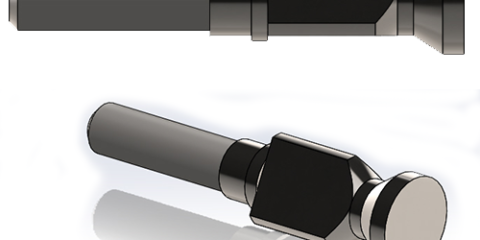

Long Life Hi-flo Swirl

The most compact swirl design that delivers equal performance in comparison to traditional larger thick swirls commonly used in many dryers.

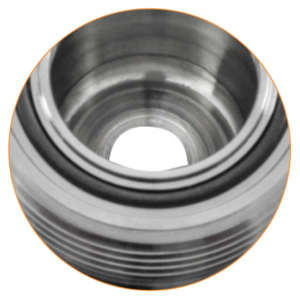

Long Life Seal-In-Disc™

The easy to clean Seal-In-Disc™ (Orifice Disc) is designed to incorporate the Orifice Disc O-ring. No O-ring groove in the Cap chamber allows for a smoother internal cap.

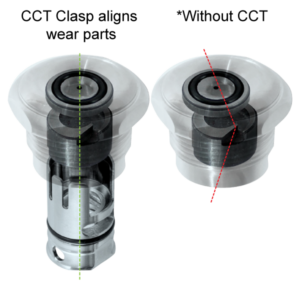

CCT Wear Part Alignment

Achieve perfect wear part alignment, better spray performance and increased wear life.

Large anti-galling threads

Heavy-duty larger threads, which are highly resistant to normal impact damage during lance handling, thus reducing thread galling and damage. Refer to our Warranty page for more information.

Seal Face Protection Skirt

World’s first unique heavy-duty dual seal face protection designed for protection against O-ring seal groove damage.

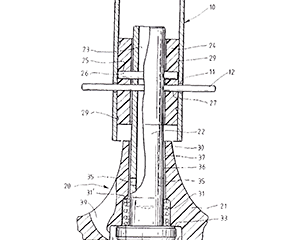

Full Axial Compressive Seal System~

Minimise Body Seal damage and leakage. The Body Seal is only in contact with the sealing surface once assembly is fully home. Eliminating old style radial seal body o-ring pinch damage, during assembly.

Seal Retention

Keep the body o-ring exactly where it needs to be. Benefit faster change outs; reduced o-ring misplacement and safer operation.

Smooth Cap Design

With no seal groove in the Cap chamber, CLICK&DRY™ internal Cap surface is smooth making cleaning and maintenance easier, with better hygiene outcomes.

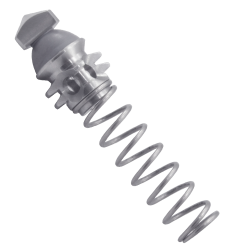

Drip-Pro™ Check Valve Technology

Reduce the problem of dripping and scorched particles. Available for sale independently or with all Click&Dry™ series.

Hygiene

- Smooth Cap chamber hygienic design and no dirty O-ring groove for easy cleaning within the fluid path

- Low Cap profile – less product build up (bearding)

- Larger thread design for easier cleaning

- Unique design eliminates the need for thread anti seize and o-ring lubricant

Improved sealing to prevent leakage

- Full Axial Compressive Seal System, exclusive to CLICK&DRY™, ensures all seals are only in contact with sealing faces once assembly is fully screwed home. This prevents seal drag and tear.

- Axial Compressive Seal System, an exclusive feature of CLICK&DRY™, ensures all seals are only in contact with sealing faces once assembly is fully screwed home. This prevents seal drag and tear. Only available with Compact and SuperMaxi Series.

Easy to use

- No Assembly Error Push-Fit Retainer Design offers improved wear part alignment and longer wear part life.

- A range of tools and accessories designed for easy assembly and to minimise carbide damage.

- Concentric Clasp Technology (CCT) – available for assemblies with CCT Clasp. With CCT Clasps, you can only assemble one way, the right way, eliminating errors.

- Easy-Out CCT Clasp Assemblies offer “No Wear Part damage extraction” when used with CLICK&DRY™ Tools ensuring longer wear part life along with 2-year breakage cover on wear parts.

Designed for Code Compliance

- Unique fully Axial sealing and FEA designed nozzle caps and bodies. Deliver NO GAP seal arrangements to prevent seal failure while assisting compliance to pressure piping codes and reducing operating risk.

- No gap fully Axial Compressive Seal System designed to minimise seal rubbing and tear damage, while delivering sealing compliance at the highest industry operating pressures.

Long Life Wear Parts

- Seal-In-Disc ™ (Orifice Disc) Technology and Hi-Flo Swirl are unique design features exclusive to CLICK&DRY™. This innovation delivers improved spray dry nozzle work-flow, powder quality and long term cost saving.

- Concentric Clasp Technology (CCT) – available for assemblies with CCT Clasp. The ultimate solution that ensures perfect wear part alignment and improves wear part life. Select assemblies with Easy-Out CCT Clasp come with 1-year wear cover guarantee from date of commission.

Lower operating cost

- Significant savings in on-going costs are achieved by reducing tungsten carbide component breakages and wear. Our innovations are designed to prolong wear part life. Upgrade to CLICK&DRY™ Easy-out CCT Clasp systems to receive 1-year wear cover (excluding Retainer System) and 2-year breakage cover on wear parts (Conversion CCT Clasp exclude breakage offer).

High Strength

- Seal Face Protection Skirt helps protect Body O-ring groove and seal face damage. Only available in Compact and SuperMaxi Series.

- Stronger and longer lasting Cap design with no seal groove inside cap chamber eliminating weakness points.

- Larger anti-galling thread design minimises thread galling. (Refer to our Warranty page)

New cap profile design

- Seal-In-Disc allows for a lower cap profile to further reduce product build up (bearding), allowing for longer product runs. The design avoids compromising material strength to meet high pressure requirements.