Leading spray dry nozzle safety company, Spray Nozzle Engineering, has released a totally new generation of Spray Dry Nozzle Check-Valves.

Called the GEN-4 Drip-Pro, the system was designed in response to the problem of post drier shut down dripping, where the latent line pressures can continue the flow or dripping of either concentrate or flush water or both; into a cooling chamber or worse, down into the vibrating fluid bed (VFB).

In many driers, this dripping can occur at the end of the run or after flush, where in each situation either you have concentrated drips leading to scorched particle deposits and final product contamination, or the dripping of nozzle flush water into the chamber or bed, causing contamination and cleaning problems.

Stuart said that many of our customers like Click&Dry check valves. Although the check valve primarily stops a wet Bottom which starts to make lumps in the fluidised bed which can slowly grow to form larger “snowballs”, to the point that they may have to shut the process down leading to costly down time and cleaning; all of which can be avoided by the Drip-Pro valve that simply drops straight into the existing Click&Dry Nozzle system, he said.

Spray Nozzle Engineering has received awards for its products for many decades and is at the fore front of drier safety and risk mitigation in nozzle technology. The Drip-Pro Gen 4 Valve is no exception, being designed to function reliably within the milk fluid path and difficult service conditions, especially viscous products such as infant formula (IF) and Nutritionals, allowing longer run times even with a check valve installed.

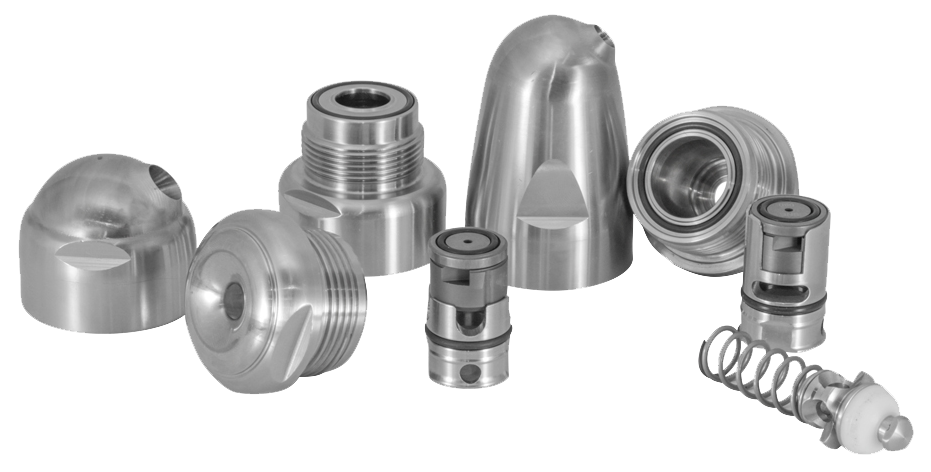

As seen in this picture of a “long run” Drip-Pro check valve after 19 hours on high solids with end of run flush. Spray Nozzle Engineering can suggest the right check valve for your spray dry application.

Available to run on all drier types, designed with long term serviceability in mind, the Hi-Flo Drip-Pro is just part of their complete range of Click&Dry nozzle safety products. Learn more visiting: spraynozzle.com or contacting them direct: sales@spraynozzle.com