The Drip-Pro Gen 4 valve was designed to function reliably within the milk fluid path and difficult service conditions, especially viscous products such as infant formula (IF) and Nutritionals, allowing longer run times even with a check valve installed.

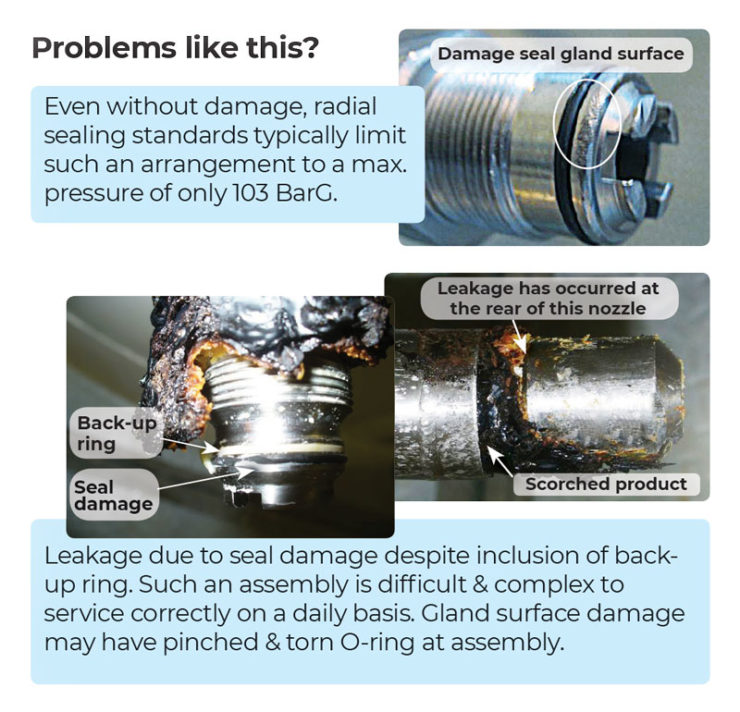

Assessing HAZOP and Hygiene Design Requirements in Reducing Chemicals and Increasing Assembly Safety With spray driers now being specifically built to manufacturer higher yield products such as nutritional and specialty powders, many process and quality professionals are looking at “how can we assemble, operate and increase cleanability of nozzles, meet our stringent audit, HACCP and […]

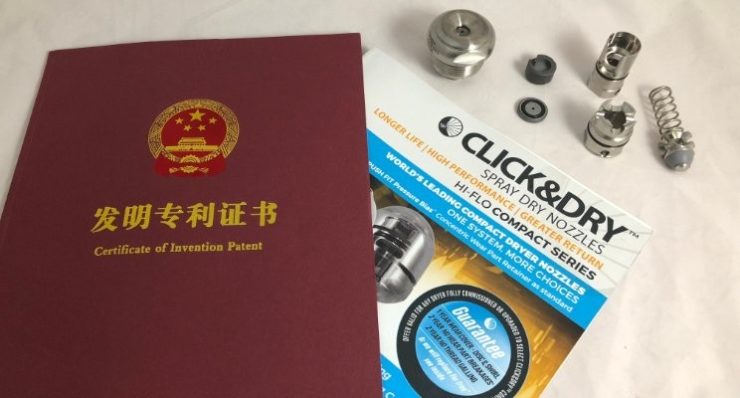

Spray Nozzle Engineering has launched a new Compact Spray Dry Nozzle at the Food Tech Pack Tech Show in New Zealand. The new Click&Dry nozzle, with a 2 year warranty in parts, is the world first design for improved spray-dry nozzle hygiene.

Australian and New Zealand based Spray Nozzle Engineering, continues expanding its Technology, with the Awarding of its First Chinese Patent relating to Spray Dry Nozzle and Check Valve Innovation. Stuart Morgan, Food & Beverage Technical Manager explains: “Spray Nozzle Engineering’s export is growing thanks to our new innovation from over a decade of product development. […]

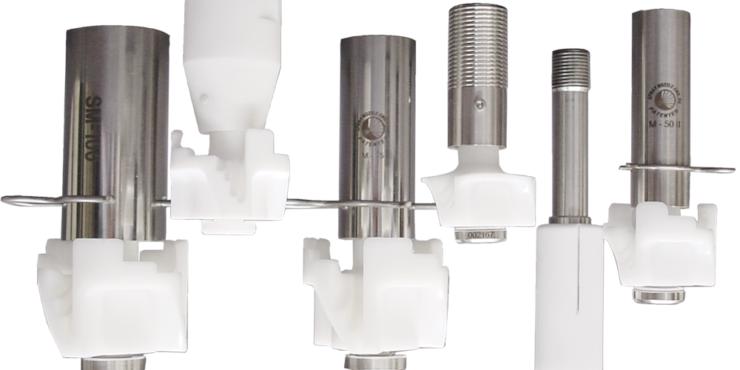

M-Series C.I.P spray nozzles are designed to provide superior tank cleaning results at low operating pressures. As a direct replacement for spray balls in standard pressure applications, the M-Series rotating action utilises Flow-Step™ Technology – concentrated streams of higher impact liquid delivering more efficient distribution, greater impact and faster C.I.P cycles*. This means less waste water and chemical treatment costs, saving you time and money.